Introducing Omron Adept Application Products

Omron Adept Industry Application Products

Packaging Automation Cells, and Flexible and Intelligent Part Feeders:

Adept's application products complement your existing wokcell and factory automation applications. The new packaging automation cell provides a prefabricated platform for primary packaging applications. Our flexible feeders and intelligent feeders provide your application with the ability to handle a wide array of parts that no conventional part feeder can match. Both products incorporate best-in-class products, deliver faster integration and make part changeovers quick and easy.

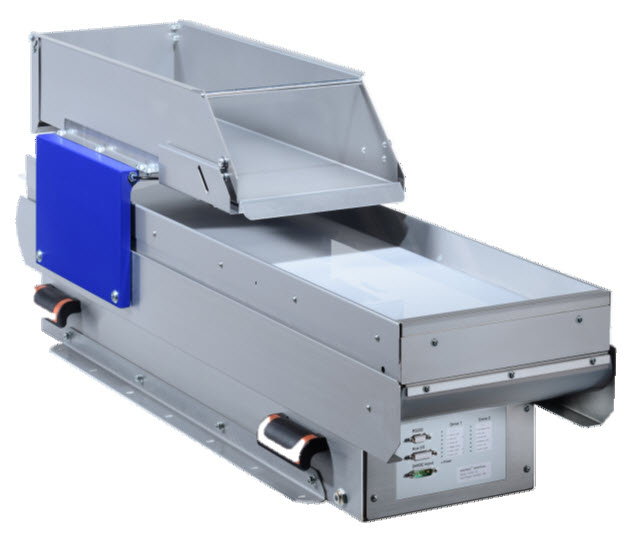

Adept AnyFeeder™

The Adept AnyFeeder™ provides an economical alternative to well-known, conventional part-feeding techniques. When combined with an Adept robot and Adept vision guidance, the Adept AnyFeeder provides flexible part-feeding that exceeds the capability of hard-tooled bowl feeders. Its flexibility in feeding small parts of various size, shape and material allow for fast line changeover and significantly reduced tooling costs, to give you a crucial competitive advantage.

Product Features

- Brushless servo drives operating system

- Rugged, conveyor-less design

- Integrated bulk feeder

- Precise part presentation platform

- Quick change feed surfaces

- Fast feed, flip, purge

- ESD feed surfaces

- Stainless steel design

Benefits

- Feeds a multitude of products

- Eliminates multiple feeder systems

- Rapid part changeover

- Dual configuration further increases productivity

Adept FlexiBowl™

The Adept FlexiBowl is an innovative feed solution for use with any Adept robot and vision system. The feeder is designed to handle a wide array of loose small parts including parts of different shapes and materials. The feeder is capable of carefully and quickly feeding parts that are tangled or made of different materials such as rubber or silicone or parts that are fragile, cylindrical or even oiled. Utilizing a direct-drive motor, the Adept FlexiBowl operates reliably and quietly and is extremely easy to operate. Its circular band tracking permits the removal of parts during movement delivering higher throughput and its unique design delivers a more flexible and efficient alternative to traditional vibration feeders. The Adept FlexiBowl is available in a 350 mm and 500 mm diameter models.

Product Features

- Direct drive

- Serial interface connections

- Encoder latching

- Infra-red backlighting

- Status LED

- Interchangeable conveying surface

- Small foot print

Benefits

- Handles a variety of parts

- Throughput of 30 - 60 parts/minute

- Fast part exchange

- Simple but robust construction

- Extremely low noise