Omron Electronics

Compact Vision Sensor with Crystal Clear Imaging

Omron Industrial Automation introduces the compact FQ-series vision sensors, a groundbreaking inspection solution for packaging applications that combines high speed, true color processing capabilities with built-in high power LED lighting and lens, for an easy-to-use, affordable system. With camera and image processor in the sensing head, FQ vision sensors offer a choice of PC or optional TouchFinder terminal for setup and monitoring. Omron’s simple and intuitive icon-driven menu system eliminates the need for complex instructions and specialist know-how.

The first products of their type to employ high dynamic range (HDR) technology, FQ vision sensors incorporate full color processing (up to 16.7 million colors), built-in polarizing and halation filters to remove glare for perfect contrast, and integrated high-intensity LED lighting. These features enable them to provide stable inspection even with highly reflective, low contrast and similarly difficult targets where conventional vision sensors see nothing. They also cope easily with piece-to-piece variation between targets and with target misalignment. Models offer up to 32 simultaneous inspections within a scene, ideal for inspecting complex confection placement and color of individual pieces in a single pass. FQ vision sensors also excel in label inspection, cap inspection, date code, and color/flavor identification.

Key Benefits

Easy-to-Use — 3 step control via intuitive icon-driven menu

True Color — Discriminate between 16.7M colors

Crystal Clear images — Unique algorithms and tools offer top quality image inspection

Accurate — Image Processing resolution is 752 x 480 pixels

Logging — Inspection history available and can be saved in SD Cards

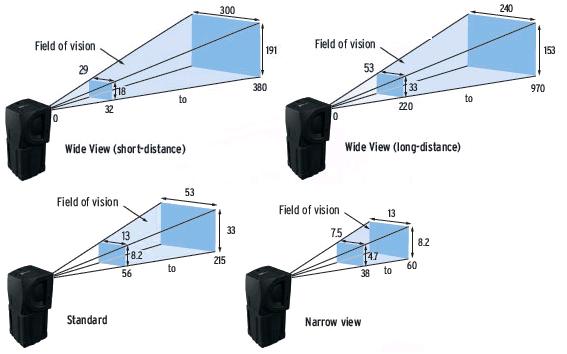

Versatile — Four different field of view (FOV) cameras to best match your application

Flexible — Touch-finder or PC set-up; Local or remote, Portable or Fixed

Single/Standard camera models — Single cameras perform one inspection; standard

cameras perform multiple inspections (up to 32 simultaneously)

Reliable — Inspect nearly any surface type: Glossy, shiny, reflective, etc.

What Makes FQ So Different?

Omron’s unique and patented Double-Reflection LED’s integrated into the FQ sensor/camera illuminate the target object in even, consistent direct lighting that eliminates the need for costly external lighting equipment. The illumination level can be manipulated from bright to dim and inbetween to achieve the ideal lighting for the application.

High-Dynamic-Range (HDR) processing eliminates halation (hot spots) for superior image captures of glossy and highly reflective surfaces. Omron’s advanced HDR technology increases the dynamic range of the image more than 16 times that of a conventional vision sensor. Without HDR, the halation phenomenon can often result in unstable and unreliable images and inspections. A polarizing filter provided with every FQ camera assists in cutting out specular light reflections from highly reflective objects, leading to an even higher degree of image quality, and hence, more reliable and consistent inspections.

Real Color image processing in a low-end vision sensor gives the FQ the ability to “see” image details competing sensors miss entirely. All competitor vision sensors within this category utilize grayscale image processing due to the high demand and associated cost of processing real color images. The FQ vision sensor combines a high-power processing unit along with real color processing technology to offer 24-bit real color images that can discriminate between 16.7M colors.