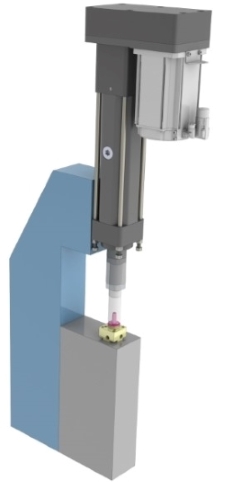

Servo Press by

Omron and Tolomatic

Introduction to the Servo Press

Servo Press is a press machine that uses a servomotor as the drive source, in applications where hydraulic presses are normally used. A hydraulic actuator must wait for the pressure to build until force is achieved, where as an electric actuator the force is generated instantaneously. This means the servomotor can control both the position and speed of the output shaft compared to a constant cycle speed.

How can it replace hydraulic cylinders?

Electric rod-style screw actuators are replacing fluid power in high-force applications throughout industry. Tasks once limited to hydraulic and pneumatic cylinders such as pressing, holding, lifting and spot welding are now being performed by electric actuators that offer lower life-cycle costs.

The development of Tolomatic's high force electric actuators has made it possible for customers to replace their hydraulic systems. Presses are capable of up to 50,000 lbs of force! They are more flexible, precise and reliable than hydraulic counter parts. Roller screw technology withstands higher loads and shocks while allowing you all the control you need in your system.

What Process Improvements Do Servo Presses Offer?

- Complex part geometries can be formed, while maintaining dimensional precision

- Adjustable stroke! The motion can be programmed for different profiles to accommodate multiple types of presses

- Less frequent maintenance, and no seal replacements

- Infinite control over position, velocity, acceleration, deceleration, output, force and more

- Overall smaller footprint, for smaller more efficient machine design

How To Replace Hydraulics with a Servo Press

There are a few considerations to take into account when replacing a hydraulic with a servo system. There is always the danger of over sizing the electric actuator. Fluctuation in fluid powder is common, and very regularly oversized - which is something the engineer usually considers as insurance. However, over sizing can obscure the actual force requirements for the application, making them appear quite high when they actually may be significantly lower than the cylinder rating.

This is because as the cylinder gets larger the force applied grows rapidly. Force = Pressure X Area, as the bore size increases so does the pressure. This can be a lot to take on! Keep reading see the Servo Press Solution Lakewood Automation can help you build. We have the knowledge and experience to help you size, integrate and program the perfect system.

Information Links:

How to Convert from Hydraulic Cylinders to Electric Actuators and Why

One Solution

Tolomatic Actuators and the Omron Sysmac Platform bring together the latest technology for a servo press, motion control and programming solution from a single source.

- Tolomatic Actuators with high rated loading, robust and custom engineered actuators bring new power previously only possible through hydraulics.

- RSX

- RSXP

- Sysmac Automation Platform

- Sysmac Studio and Libraries

- NX1 CPU

- 1S Motor and Drive

- Ethercat network

The result: a powerful and robust automation platform and a high powered actuator brings together motion, sequencing, safety, networking for the ultimate servo press.

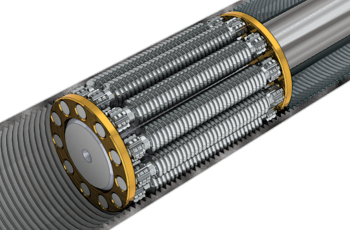

Tolomatic RSX Actuator

Meet Your New Favorite Actuator

The RSX family of extreme force electric linear actuators are more efficient and offer increased precision compared to hydraulic cylinders. Tolomatic precision ground planetary roller screws are utilized to achieve long life and precision. The RSX platform is designed and tested for long life and reliable performance in demanding conditions including cold weather operation.

The RSX Family now includes three frame sizes ranging from RSX080 with max force capability of 18,000 lbf , to RSX 128 capable of achieving 50,000 lbf max force. See the RSX096P Press Model for max forces up to 40,000 lbf in extend direction.

RSX extreme force electric linear actuators offer these features:

- Planetary roller screw driven for long consistent life

- Type III hard coat anodized aluminum housing to withstand demanding environments

- Standard thrust rod anti-rotation feature

- IP67 option to protect against dust and water ingress

- Compatible with servo motors and gearboxes up to 215mm frame sizes

- Food grade, white epoxy coating and stainless steel thrust rod option

Information Links:

Your Motor Here

Tolomatic makes mounting your motor to our actuators EASY!

Your Motor Here (YMH) is a program that Tolomatic designed to make mounting most standard motors to appropriately sized actuators easy and seamless. If the motor & actuator match, Tolomatic builds and ships the electric actuator with the required motor mounting hardware in 15 days or less. Ask us about YHM today!

Omron Sysmac Platform

NX1 Controller

Features:

- Real-time data traceability

- Secure information transfer (OPC UA server built-in)

- Safety integration

- Quality control

- Advanced machine control

Product highlights:

- Fast and accurate control by synchronizing all machine devices with the PLC and Motion Engines

- DC power supply without battery backup

- Fully conforms to IEC 61131-3 standard programming

- PLCopen Function Blocks for Motion Control allow users to create complex programs quickly and easily

Communication Possibilities:

- Up to 12 axes of control via EtherCAT

- Three built-in industrial Ethernet ports

- Up to 32 local NX I/O Units

- OPC UA server functionality

- Direct connection to a database, with no special unit, software, or middleware required

Sysmac Studio

One software to control and configure the entire machine via a single connection gives you the power and efficiency to develop and create like never before

Learn it once:

- One software for logic, motion, safety, drives, vision and HMI

- Fully compliant with the open standard IEC 61131-3

- One consistent design environment

Develop it fast:

- Supports Ladder, Structured Text and Function Block programming with a comprehensive instruction set

- Graphical CAM editor for easy development and programming of complex motion profiles

- Intuitive editor with auto-complete assistance for Ladder and Structured Text programming

Test it as one:

- One simulation tool for sequence and motion in a 3D environment

- Complete or partial program can be simulated and debugged

- Data trending for tuning and debugging

- Emulation of all Sysmac controllers functions

Secure it all:

- Advanced security function with 32 digit security password

- Complete project or single Function Block can be protected (available in Sysmac Studio above v1.)

- Machine cloning prevention

- One Intuitive Interface

Sysmac Studio Libraries

The Sysmac Library is a collection of software functional components that can be used in programs for the NJ/NX Machine Automation Controllers or Industrial PC Platform NY IPC Machine Controller. Packed with Omron’s rich technical know-how on control programs, the Sysmac Library makes advanced control easy. Install the Sysmac Library to use it in the Sysmac Studio.

For the servo press:

- MC Test Run

- MC Command Table

- Servo Press.

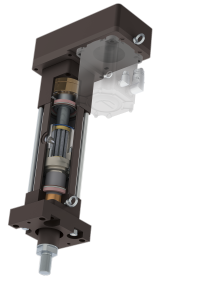

Omron 1S Servo System

Award Winning Design With State Of The Art Servo Technology

Designed to meet a variety of machine requirements, the 1S servo technology optimizes the full cycle, through the machine design, installation and commissioning tasks and finally to the maintenance once in production. In addition to the traditional motion solution, the 1S servo offers high-resolution multi-turn encoder with battery backup, safety network built-in and improved loop control, allowing accurate and higher machine productivity.

Optimized installation and commissioning tasks:

- Reduce cabinet size with compact servo drive with same height throughout the whole power range

- Fast and secure screw-less push-in in control I/O connector and brake interlock connector

23 bit high resolution encoder:

- No battery, no maintenance and compact size

Multi-axis setup and tuning:

- Configure and monitor multiple axes in one view

- Easy & fast parameter transfer among axes in the machine (up to 256 axes)

- Comprehensive gain tuning

Safety control via EtherCAT:

- EN ISO 13849-1(Cat.3 PLd)

- EN61508(SIL2), EN62061(SIL2)

- EN61800-5-2(STO)

Information Links:

EtherCat Network

NX I/O over EtherCAT

Based on an internal high-speed bus running in synchronization with the EtherCAT network and using the time-stamp function, the NX I/O can be controlled with microsecond accuracy and with nanosecond resolution. The I/O range consists of over 90 models including position control, temperature inputs and integrated safety.

NX Safety over EtherCAT

The Sysmac platform integrates a safety solution within our one connection and one software concept. One connection is realized through the use of Safety over EtherCAT (FSoE) protocol

- Fastest cycle time: 125 microseconds

- Up to 256 synchronized axes

- 512 slaves

- Embedded in Omron servo drive, inverter, I/O, Safety, Vision and Sensing

- Uses standard STP Ethernet cable with RJ45 connectors

- One connection using Safety over EtherCAT (FSoE) protocol